Formation of Sn film on small chip parts

Melplate SN-2680

Miniaturization and thinner chip components

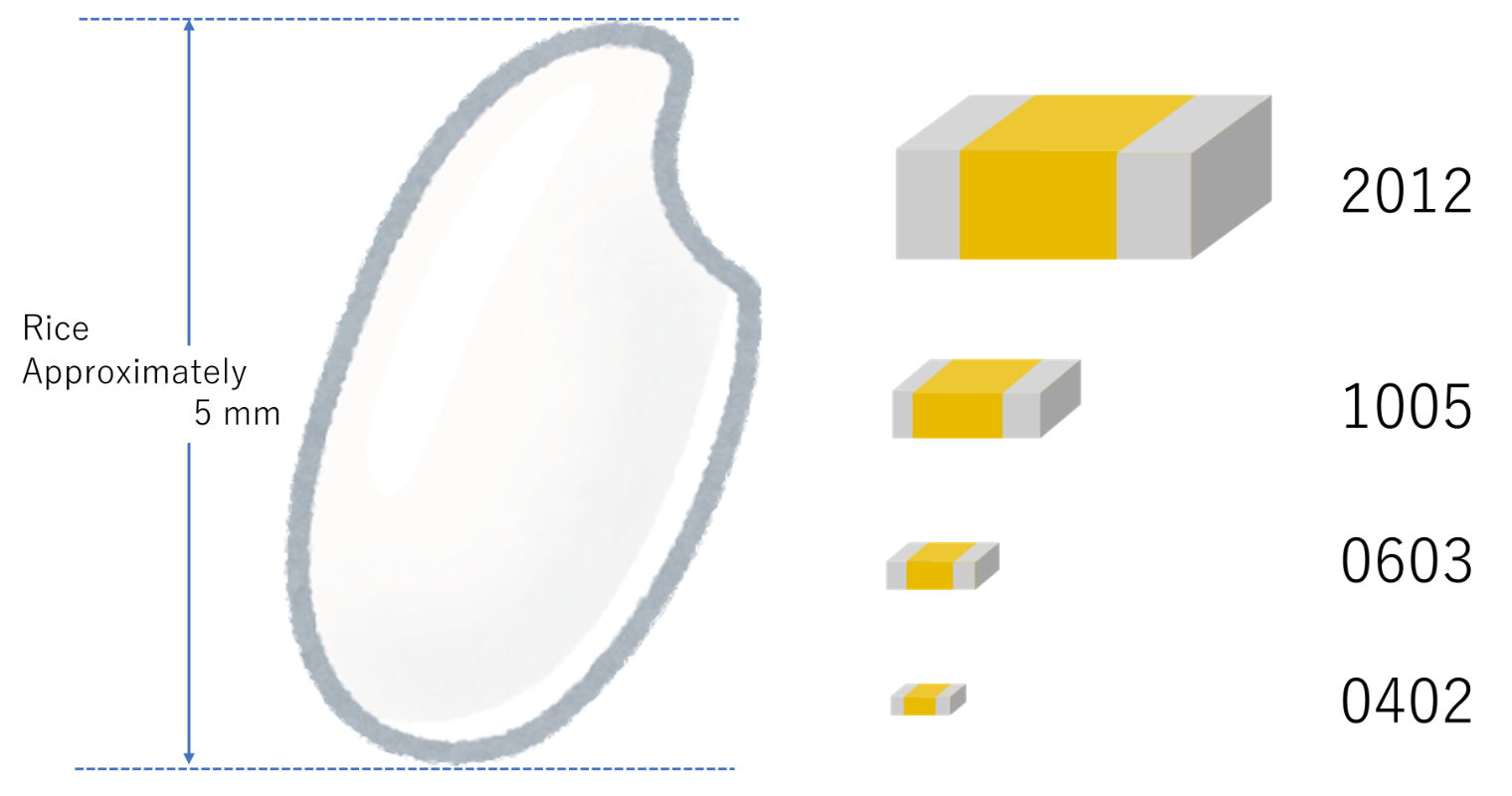

Chip components are a generic term for surface-mounted passive components, and include such types as multilayer ceramic chip capacitors (MLCCs), resistors, and inductors. Shipments of chip components continue to increase. In automobiles, for example, MLCCs, which used to number several hundred to 3,000 per car, are expected to increase to around 7,000 to 8,000 per car due to the shift to electronic and electric vehicles. The miniaturization of electronic devices has also led to the miniaturization of chip component sizes. 3216 size (3.2 mm × 1.6 mm) used to be the mainstream, but now 1005 and 0603 size (1.0 mm × 0.5 mm, 0.6 mm × 0.3 mm) are the mainstream, and by 2030 0603, 0402 (0.4 mm × 0.2 mm) size will become the mainstream. At the same time, the size of the products is becoming smaller and thinner at the same time.

Sn plating method for small and thin chip components

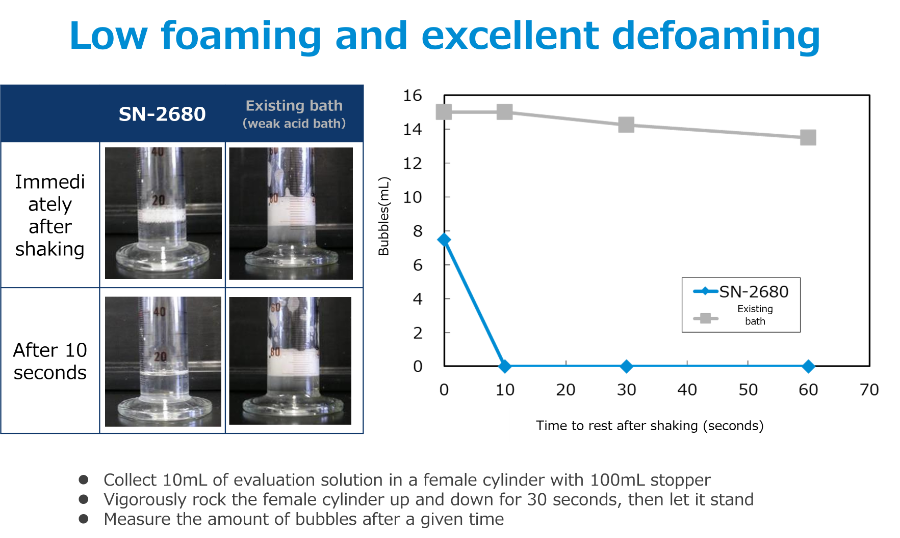

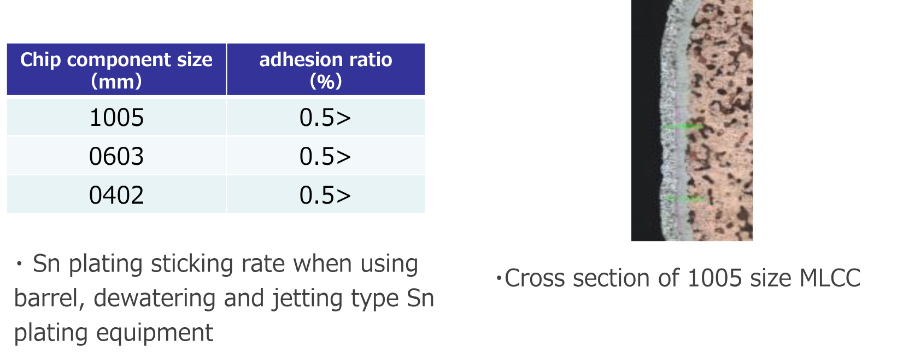

Ni and Sn plating is applied to the electrodes of chip components to ensure solder wettability. Barrel plating equipment is the most common method of plating chip components. In barrel plating, a metal ball called a dummy ball is simultaneously fed into the barrel to ensure continuity to the electrode to be plated. As chip components become smaller, the dummy balls also need to be smaller, and the smaller the balls, the more likely they are to agglomerate due to plating. Also, as chip components become thinner, they tend to stick to each other, causing plating defects.(→Reference link)Therefore, dehydrator-type or jet stream plating equipment is sometimes used for small and thin chip components. In these types of plating equipment, the liquid is agitated violently during plating. As a result, problems such as bubbles overflowing from the equipment or equipment stoppage due to malfunctioning of the liquid level sensor can occur. To solve this problem, a plating solution with less foaming is required.

Neutral type Sn plating liquid with excellent defoaming properties

- ・The plating chemicals themselves do not foam, so equipment malfunctions are not likely to occur.

- ・It can be used for all barrel, dehydrator type and jetting type Sn plating equipment.

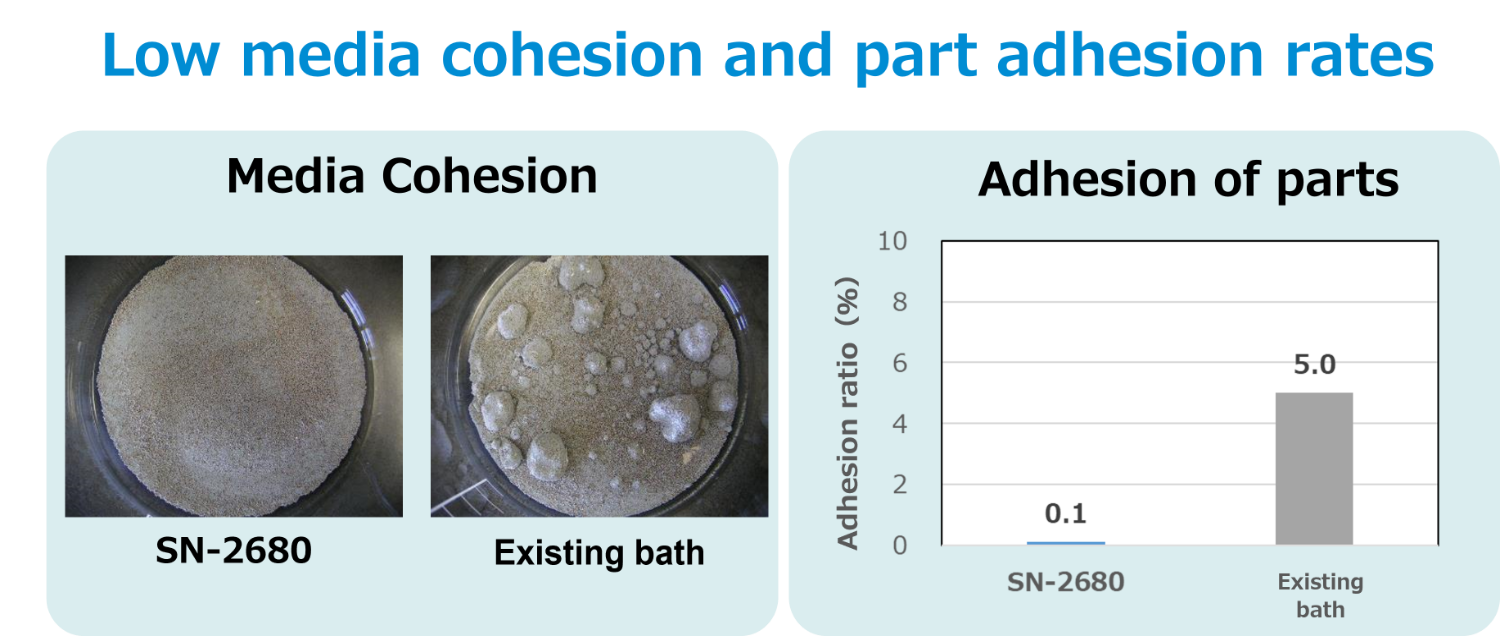

Prevents media cohesion and parts adhesion

Melplate SN-2680 features less media agglomeration and parts sticking, which is noticeable in smaller and thinner chip components.

Features of the Melplate SN-2680

- ・Due to its low foaming, it is applicable to all tin plating equipment for chip components, such as barrel, dehydrator type, and jetting type.

- ・The sticking rate of chip components can be reduced to 0.5% or less, which greatly contributes to reducing the defect rate.

- ・Uniform tin plating film can be obtained even on minute chip components.

- ・Neutrality reduces material erosion and is suitable for all passive components.

- ・Whisker generation is virtually non-existent.

Contact

Please feel free to contact us with requests for more detailed characteristic data, or to discuss applications or prototypes.

We will reply to you by e-mail first.