%{ENBMGNAVI}%

Meltex's Strengths

- We are a manufacturer of surface treatment chemicals.

- Meltex proposes cutting-edge surface treatment technologies centered on chemicals through technological development.

Meltex has four major business segments: printed wiring boards, electronic components, semiconductors, and automobiles. For the PWB segment, we provide high-performance via-fill plating chemicals and high-precision seed layer etchants mainly for build-up boards, and for the electronic components segment, we provide tin plating chemicals adapted to MLCC materials. In the semiconductor segment, we provide various chemicals for sensors and power modules. In addition, we are developing chemicals for automotive applications, which are expected to change significantly in the future, in order to meet new needs.

Since the 1970's, we have been a pioneer in the recycling of used etchant, always striving to manufacture environmentally conscious products, while at the same time reducing energy, resources, and waste.

Meltex's philosophy is "to contribute to society by solving our customers' current problems and future requirements," and we continue to develop products to meet new needs.

- Our Strengths

- Since its establishment, Meltex has been a leading company in the field of surface treatment, providing customers with a variety of methods and chemicals.

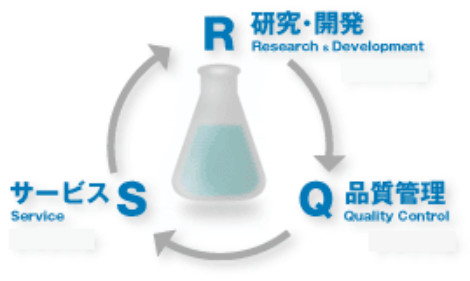

「With "One Meltex One Voice" as our basic rule, each department works in unison. Sales puts communication with customers first and makes proposals that anticipate technological trends based on interviews and other information. The Development Division creates unique and advanced technologies. Technology provides meticulous after-sales service and technical support. Production is based on strict quality control and a stable supply of products.

These are what differentiate us from our competitors and have allowed us to build a strong reputation not only in the domestic market, but also in the global market.

- High quality and manufacturing management system for global operations

- Meltex has production facilities in Kumagaya and Yokkaichi, and outside of Japan in Thailand, ensuring a global supply system for high-quality, reliable chemicals.

Manufacturing is subject to appropriate inspection items to ensure high quality, and products are shipped after in-process and final inspections. We have a system in place to quickly detect abnormal values, investigate, and make improvements through trend management by checking the trends of inspection values on a graph. By regularly checking the manufacturing process, we prevent problems before they occur and strive for improvements to produce more stable products.

In preparation for the future growth of the semiconductor market, we have completed construction of a new factory building, “SAKURA TOWER”, equipped with a class 1000 (ISO 14644-1 Class6) clean room to ensure quality and supply capabilities that meet the strict standards of the semiconductor field. The SAKURA TOWER is equipped with a class 1000 (ISO 14644-1 Class6) clean room to ensure quality and supply capabilities that meet the strict standards of the semiconductor industry.