Neutral electroplating process for chip components

For all types of chip-type passive components

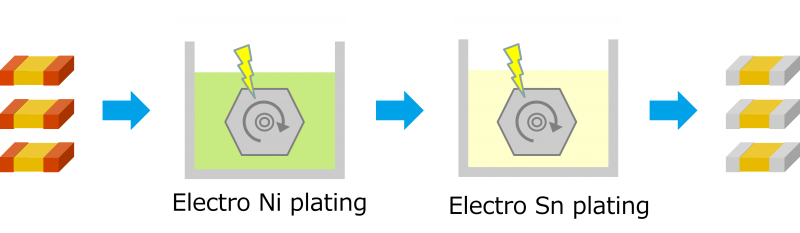

Plating process for chip components

Chip components are plated with nickel or tin on the terminals formed with copper or silver paste for mounting on printed circuit boards. Electroplating using a barrel is the most common plating method. In order to ensure continuity to the terminals of each chip component, a metal ball called a dummy ball is inserted into the barrel at the same time as the component and plated.

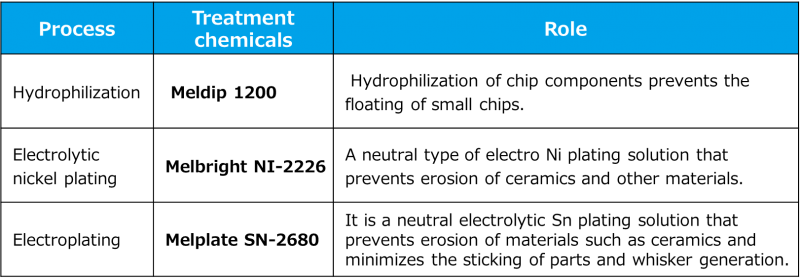

Meltex's Neutral Electroplating Process

The following issues are known to occur in the surface treatment of chip components.

- ① Unplating of small chip components due to floating

- ② Degradation of electrical characteristics due to material erosion

- ③ Sticking of chip components to each other (double adhesion)

- ④ Short circuit after mounting due to Sn whiskers

Meltex has developed a "neutral electroplating process" that solves these problems.

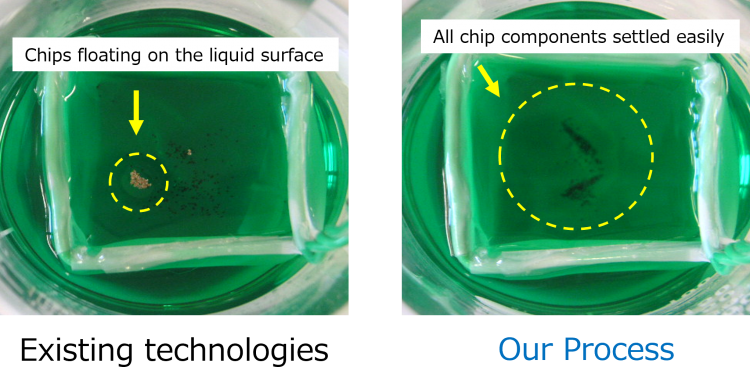

【Challenges in Plating Chip Components】①Floating of Small Components

Small chip components tend to float on the surface of the water and may not sink into the plating solution. If the parts do not sink into the plating solution, they will not be plated, leading to unplated defects.

In Meltex's neutral electroplating process for chip components, hydrophilic treatment is applied prior to electro Ni plating to prevent small chip components from floating and to prevent only plating from depositing.

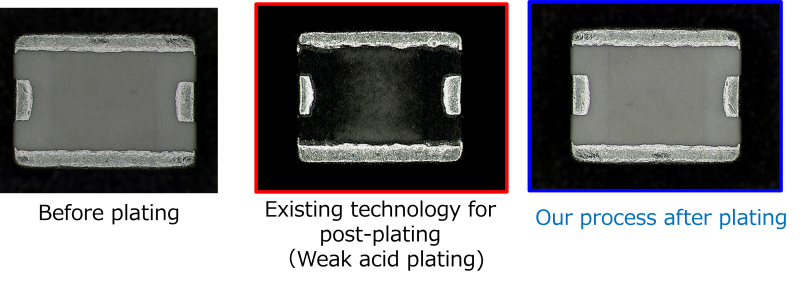

【Problems in plating chip components】②Material erosion

Depending on the type of chip component, the material may be susceptible to acid or alkali and may be eroded in the plating solution. When the material is eroded, the plating may grow out of the electrodes or the electrical characteristics may become specialized.

Meltex's neutral electroplating process for chip components minimizes material erosion of chip components by keeping the pH of the solution near neutral throughout the process.

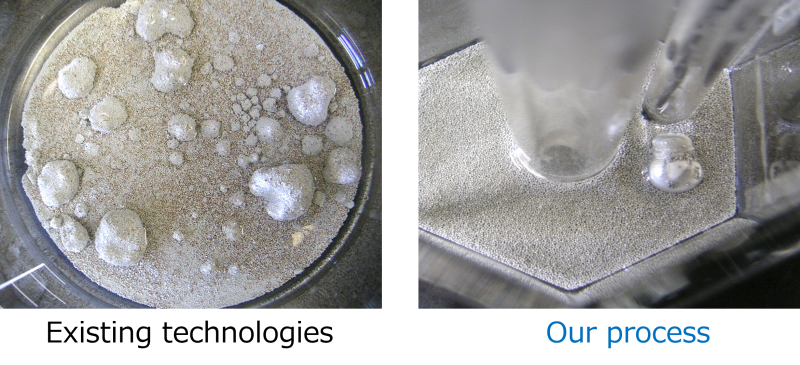

【Challenges in plating chip components】③Sticking of chip components

In the electro-tin plating process, as the plating progresses, sticking to other parts may occur, resulting in double adhesion of parts and aggregation of dummy balls. This sticking can lead to the deposition of only the plating and variation in film thickness, resulting in an increased defect rate.

Meltex's electroplating process for neutral chip components prevents sticking by adjusting the plating solution, which contributes to lowering the defect rate.

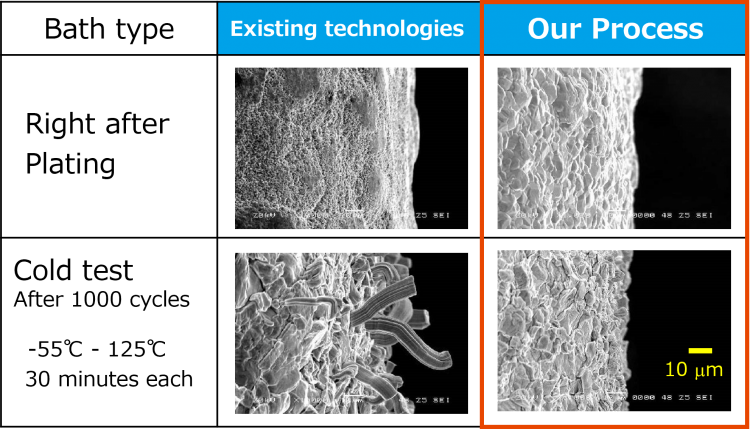

【Problems in plating chip components】④Whisker generation

Whiskers can be generated from the tin plating film due to environmental changes after parts are mounted, causing short circuits and other problems in the circuit.

Meltex's electroplating process for neutral chip components uses proprietary technology to create a plating film that is less prone to whisker generation.

Meltex's neutral electroplating process for chip components

Meltex's neutral electroplating process for chip components is a plating process with the following features

- ・The process is neutral throughout the entire process, minimizing material erosion and making it suitable for all types of passive components.

- ・Uniform Ni plating film with no floating of small parts

- ・The amount of boron used during Ni plating is less than half that of conventional products.

- ・Almost no whisker generation.

- ・Minimal whisker generation - Minimizes double adhesion of products and media agglomeration

Contact

Please feel free to contact us regarding more detailed characteristics data, applications, prototyping or any other matters.

We will reply to you by email first.