Multi-stage electrolytic sterilizer

Do you have problems with algae and biofilm?

Features of Multi-Stage Electrolytic Sterilizer

The multi-stage electrolytic sterilizer can efficiently control (sterilize) bacteria by circulating pure water, etc., in storage tanks to a compact electrolytic sterilizer.It is also effective against plant microorganisms that are difficult to treat with UV disinfection equipment.

-

- ・ High sterilization efficiency: Circulation system provides sufficient sterilization effect

・ Can be processed regardless of each animal or plant species

・ No change in water quality: Basically no change in the composition and pH of the water to be treated

・ Low running cost: only the cost of DC power supply, electricity for circulation pumps, and filters

・ Space saving: Equipment has a very compact design and is easy to maintain

- ・ High sterilization efficiency: Circulation system provides sufficient sterilization effect

It is particularly effective when pure water or ultrapure water is stored and used after production, or when pure water is repeatedly recycled in a closed system.

It can also be used for industrial water storage tanks, recovered rinse water after gold plating, and rinse water after electroless Ni plating.

Electrolytic Sterilizer Mechanism and Examples of Operation

A DC voltage is applied to the electrolytic cell to electrify the multiple electrodes in the cell. When water containing microorganisms is allowed to pass through the cell, the microorganisms come into contact with the positively charged electrodes and are inactivated and killed by an oxidation reaction. As a result, most of the initial microorganisms are sterilized within a few hours after the start of electrolysis.

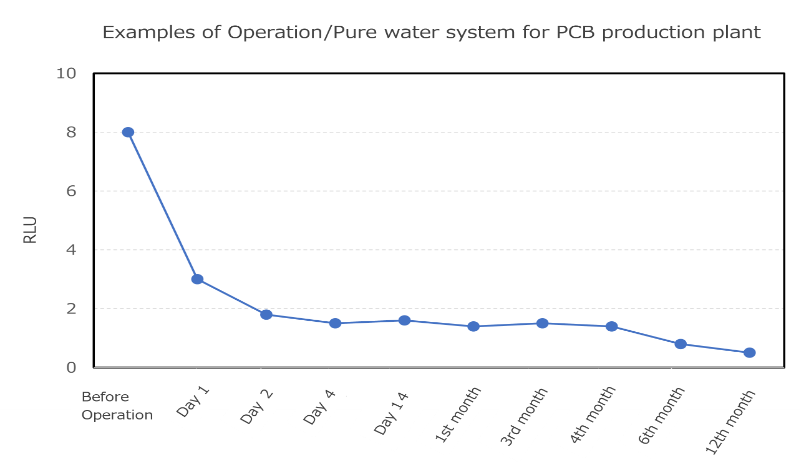

The graph below shows an example of operation when a deionized water production system was installed at a PCB production plant. As shown in the graph, the RLU value decreased immediately after the electrolytic sterilization system was put into operation, and remained low without increasing even after one year of operation. The RLU value is the output value from the ATP test and corresponds to the amount of ATP (adenosine triphosphate), which is considered an indicator of biological contamination in the water.

Although a UV sterilization system has been incorporated here, the plant has been plagued from spring to fall by the adhesion of foreign substances of biological origin on the workpieces, which has been improved by the introduction of an electrolytic sterilization system.

※RLU values were measured by LumiTester Smart (Kikkoman BioChemifa).

This system has been used by more than 20 manufacturers of printed wiring boards and electronic components and various processing companies in Japan and overseas.

Comparison with other sterilization methods

The sterilization method by electrolysis is superior to other sterilization methods, especially in terms of sterilization effectiveness and running costs, and has less impact on treated water and environmental impact.

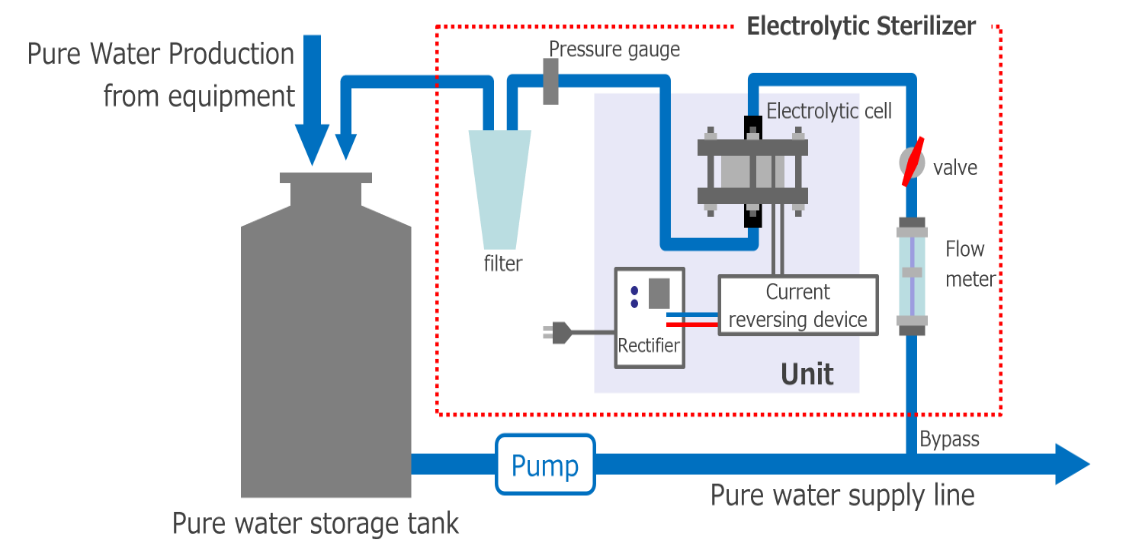

Equipment flow diagram

Electrolytic sterilization equipment can be installed according to your equipment conditions.

It can be used simply by inserting it into an existing or newly constructed circulation line. It can be installed as an integrated unit (red box in the figure) or as a unit with electrolysis cells, power supply unit, etc. We recommend installation of the unit type from the viewpoint of installation location.

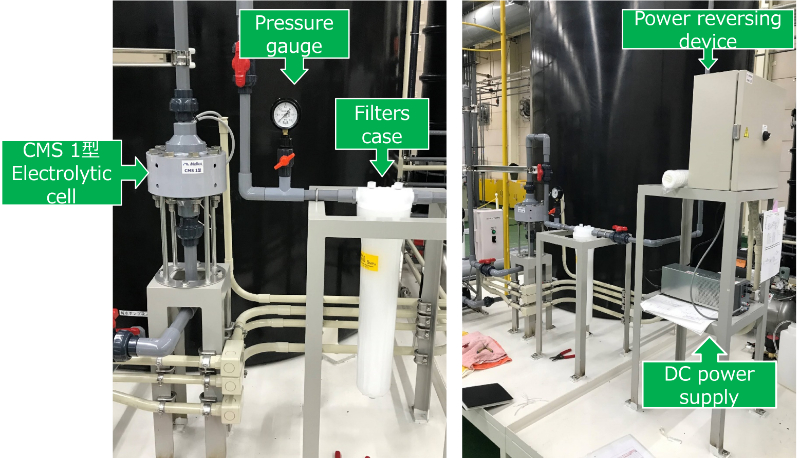

Installation example

It can be incorporated as a unit into existing and new pure water production equipment.

Contact

Please feel free to contact us with requests for more detailed characteristic data, applications, or inquiries about prototypes. We will reply to you by e-mail.