DFR Developer Residue Remover

Protect fine circuits by eliminating undercut and void defects!

Melstrip DS-3311

Key Challenges in Using Dry Film Resist for PCB Fabrication

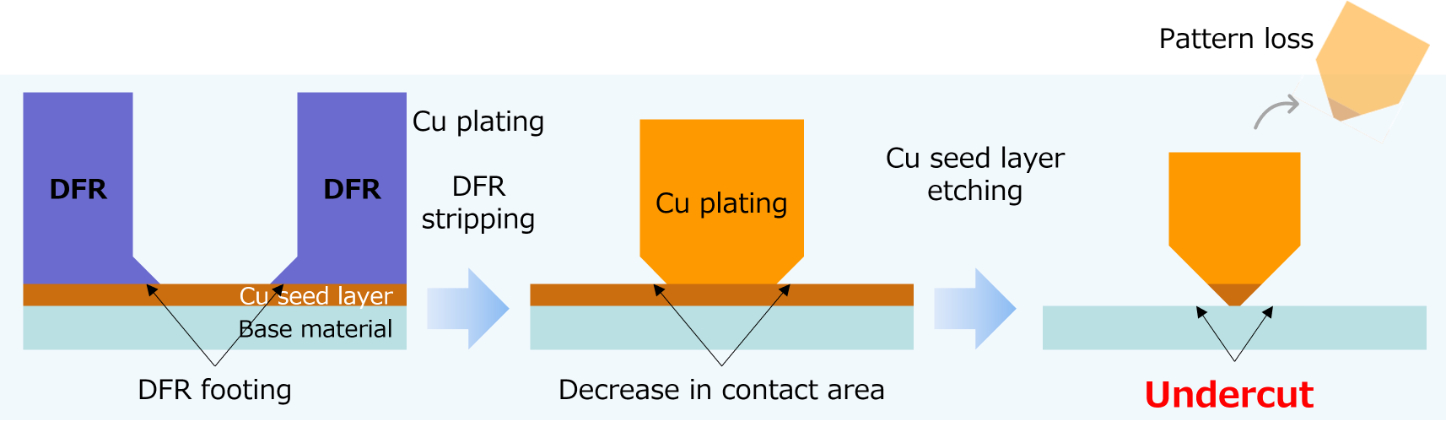

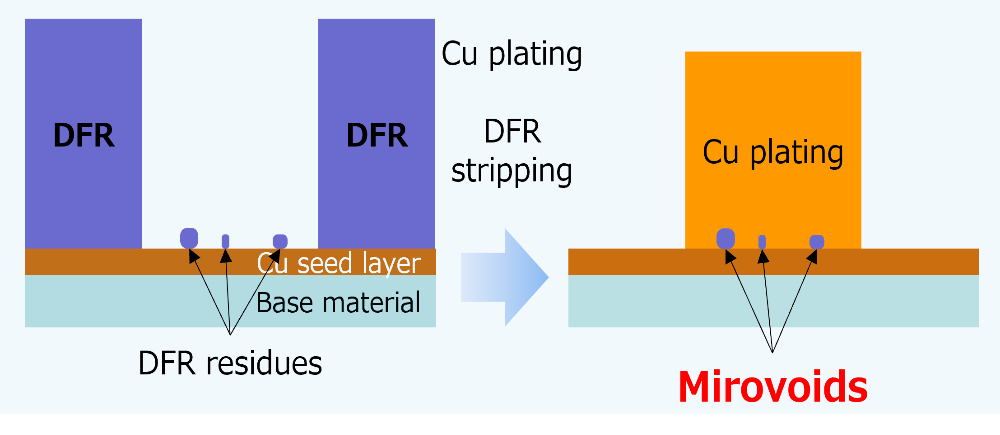

In recent years, the demand for higher performance in electronic devices has driven rapid miniaturization of printed circuit boards (PCBs). As a result, the development accuracy of dry film resist (DFR) during the manufacturing process has become a critical factor directly linked to product reliability. In particular, fine residuals left after DFR development can adversely affect subsequent processes such as copper sulfate plating and seed layer etching, raising concerns about undercutting, micro-void formation, pattern defects, and reduced connection reliability.

Issues Caused by DFR Development Residue

During the DFR development process, partially exposed residues tend to remain at the base of fine patterns. When these residues adhere to the copper seed layer and proceed to the next step, the following defects may occur:

□Increased Undercut Formation

□ Formation of Micro-Voids

In the past, circuit widths were relatively large, so the impact of DFR foot extension and residuals was minimal. However, in today’s manufacturing environment, where miniaturization is advancing rapidly, much higher precision in removing DFR development residues is required.

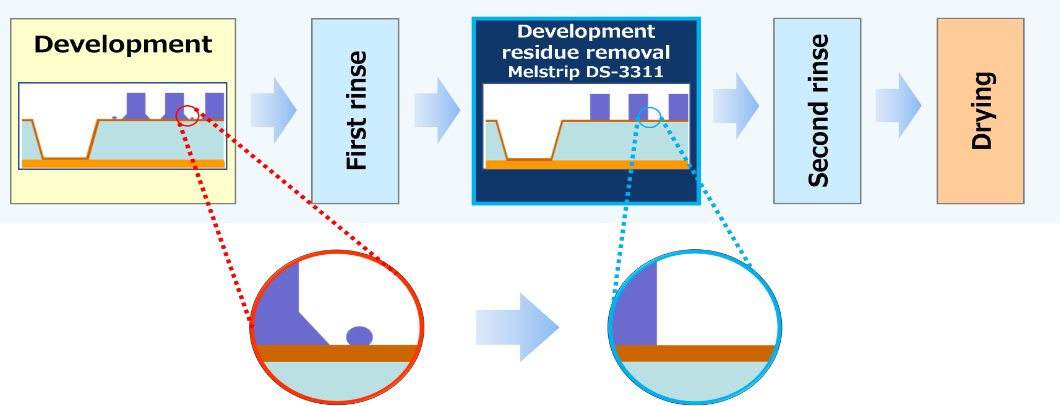

Introduction of DFR Developer Residue Remover

In response to these challenges, we have developed the DFR Developer Residue Remover “Melstrip DS-3311.” By incorporating this solution into the post-development rinsing process, it effectively eliminates residues before the dry film undergoes hardening, ensuring surface cleanliness and process reliability.

This process suppresses the occurrence of undercutting and microvoids in subsequent steps, contributing to pattern shape stability and improved connection reliability.

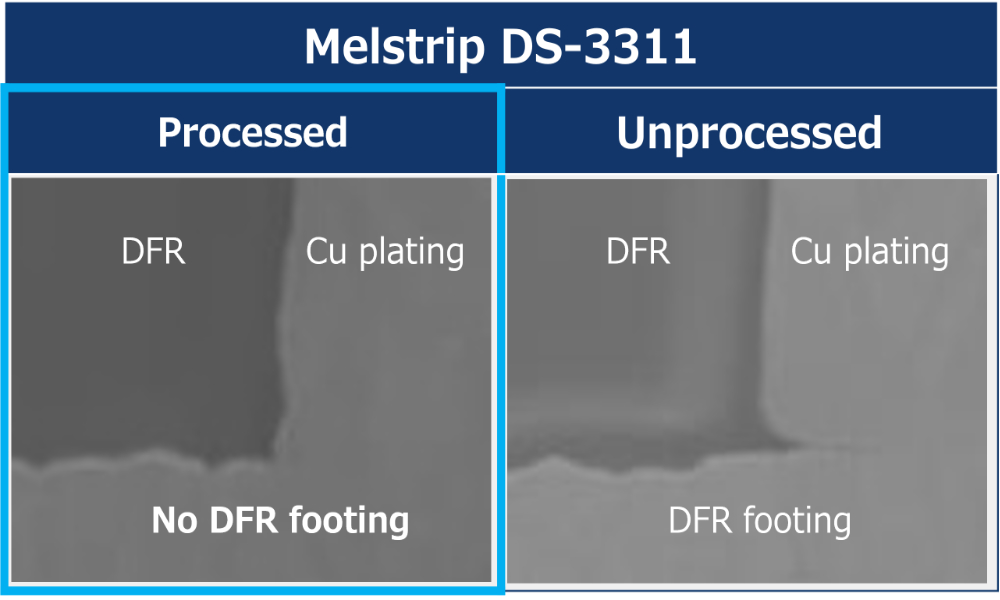

Effect of Developer Residue Removal Process

The following differences have been observed between processes using Melstrip DS-3311 and those without it.

Melstrip DS-3311 is a processing agent with the following features:

- ・Compatibility with Fine Circuits: High performance in removing DFR foot residues, ensuring reliable processing even for fine patterns.

- ・Improved Connection Reliability: By removing DFR residues and suppressing microvoid formation, this process enhances the reliability of interconnections with the underlying copper.

- ・Seamless Integration into Existing Processes: Can be implemented by utilizing the current rinsing step.

- ・Environmental Compliance: Does not contain environmentally hazardous substances.

Removing DFR developer residues is a critical process that directly impacts product quality in the increasingly miniaturized manufacturing of printed circuit boards. The introduction of Melstrip DS-3311 enables process stabilization and improved reliability.

Contact

Please feel free to contact us regarding more detailed characteristics data, applications, prototyping or any other matters.

We will first answer you by email.