Melplate UBM Pretreatment Process

UBM Formation Technology

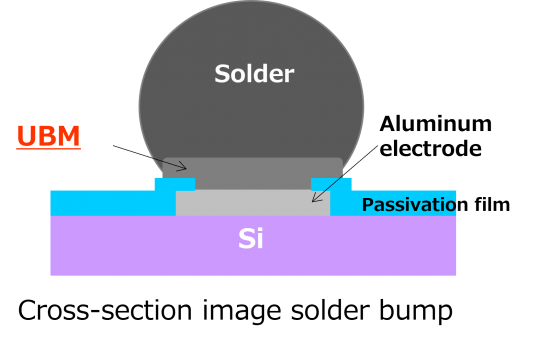

With the flip chip method, semiconductor chips are connected to the mounting board via bumps. UBM is formed on the interface between the aluminum electrode on the chip and solder as a barrier layer that constrains interdiffusion. UBM stands for Under Bump Metal or Under Barrier Metal and consists of nickel / gold, nickel, palladium / gold, etc. UBM is formed to ensure barrier properties and protect the surface at solder joint.

UBM Formation Using Electroless Plating

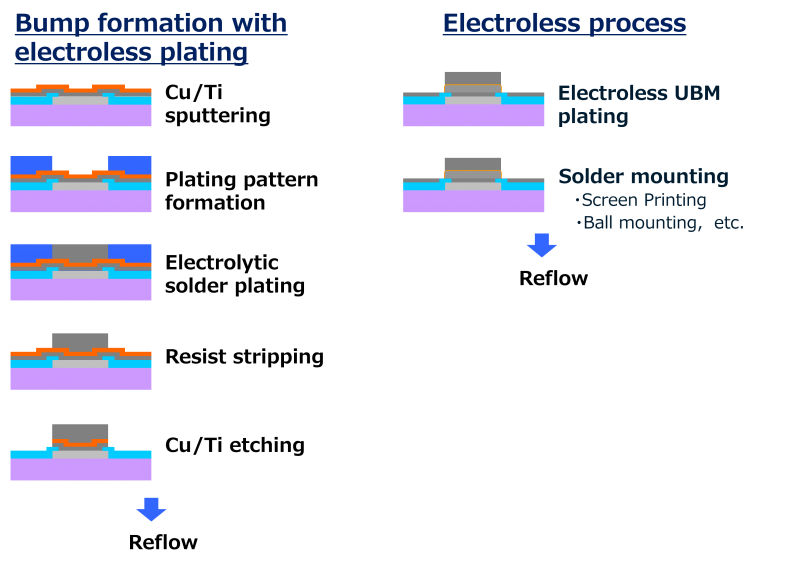

Electrolytic plating and electroless plating are available to form UBM with plating. The Melplate UBM process provided by Meltex forms UBM with electroless plating.

Electroless plating can be used to selectively form a plating film on the metal electrode. Therefore, bump formation does not require exposure and image development processes and the film can be formed without using resists. Electroless plating is also advantageous in that the height of the UBM and solder bump is stable.

Great pretreatment in the Melplate UBM process

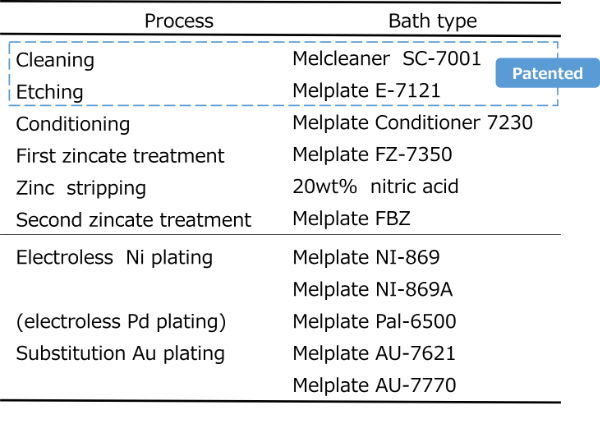

Pretreatment in the Melplate UBM process is a treatment process that optimizes each process that includes patent technologies to address“various types of aluminum electrodes and minimizes damage to electrodes to form extremely smooth UBM.

Electroless plating forms Ni/Pd, Ni/Pd/Au, or other UBM after this pretreatment process.

Pretreatment Independent of the Type of Aluminum Electrode (Patented Technology)

Aluminum electrodes can be made of aluminum alloys such as Al-Cu, Al-Si-Cu, and Al-Si in addition to pure aluminum. Zincate treatment can be uneven and cause plating appearance faults depending on the type of aluminum alloy.

The pretreatment in the Melplate UBM process allows for pretreatment independent of the type of aluminum electrode with patented etching and conditioning treatment, which makes later zincate treatment even. This process also supports different plating film thickness and plating deposition failure due to potential difference or orientation difference of electrode that occurs during design.

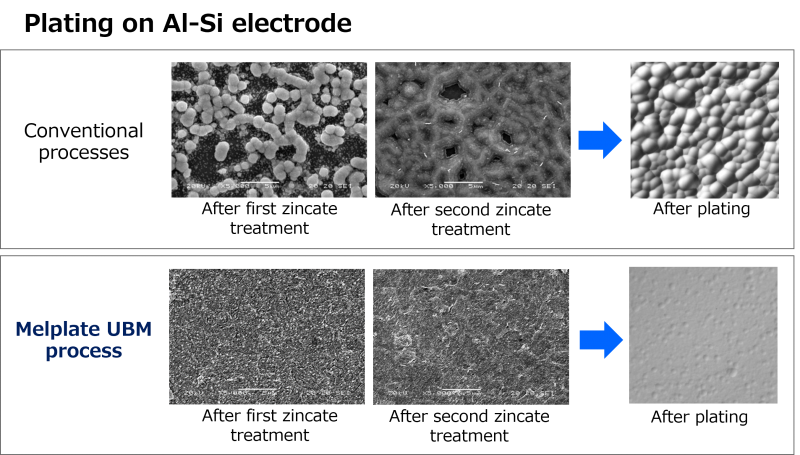

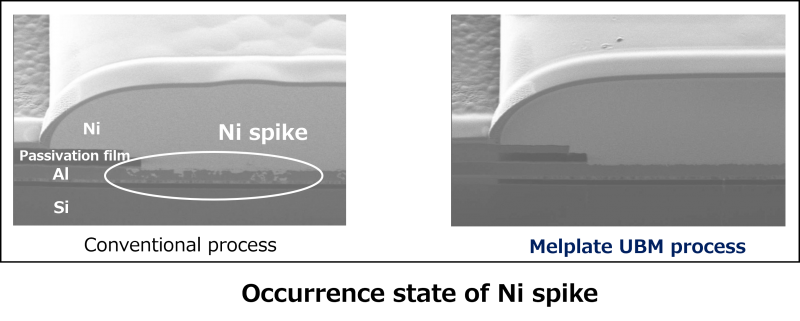

Zincate treatment to Reduce Nickel Spikes

Zinc substitution treatment, called zincate treatment, is required to apply electroless plating to aluminum electrodes.Although the same chemicals are usually used for the first and second zincate treatment, the purposes of the first and second treatment are clarified and chemicals for their individual purposes are prepared in the Melplate UBM process.

The first zincate treatment is optimized to eliminate local corrosion on aluminum electrodes whereas the second zincate treatment is optimized to achieve high adhesion of plating film. This minimizes nickel spikes after plating and achieves high adhesion of plating film.

Features of the Melplate UBM Process

The Melplate UBM process is designed to form plating films of electroless nickel gold or electroless nickel palladium gold on aluminum electrodes. The pretreatment process in the Melplate UBM process has the following features:

- ・Little damage to aluminum alloy electrode

- ・Not dependent on aluminum alloy type

- ・Little influence by electrode potential

These features result in the formation of highly adhesive electroless plating film that has a smooth surface and is free of nickel spikes on the interface between aluminum and electroless nickel.

Contact

Please feel free to contact us regarding more detailed characteristics data, applications, prototyping or any other matters.

We will reply to you by email first.