Seed Layer Etchant for MSAP

Supports smooth circuit formation to reduce transmission loss

Seed layer etching

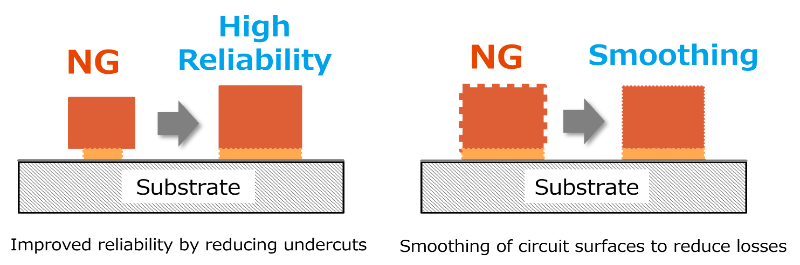

In circuit formation using the semi-additive process (SAP) or modified semi-additive process (MSAP), a copper seed layer remains on the substrate after dry film removal. By etching this copper seed layer, an insulated independent circuit is formed. Currently, sulfuric acid-hydrogen peroxide etchant is the mainstream etchant, but there are still issues regarding chemical stability due to hydrogen peroxide, etching speed control due to contamination with different metals or chlorine, and copper pattern protection performance. In addition, there is a strong need to reduce undercuts to improve connection reliability and smoothness of circuit surfaces to reduce transmission loss.

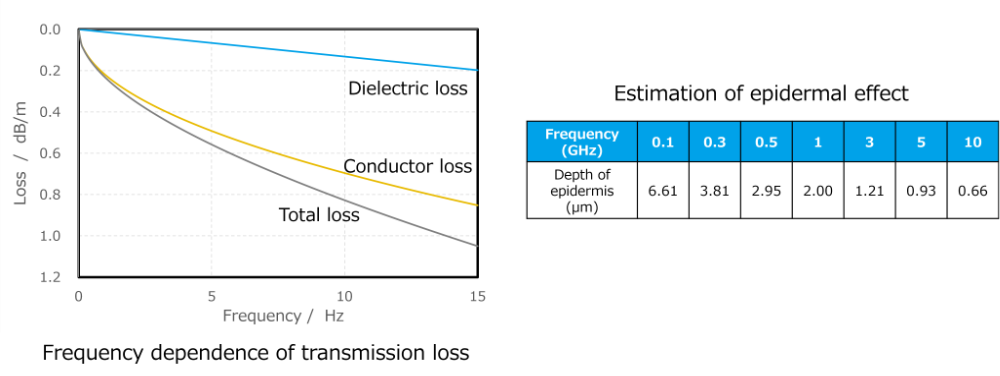

Transmission loss of conductors

Transmission loss is expressed as the sum of dielectric loss, which is related to the dielectric constant of the insulation layer, and conductor loss, which is related to the smoothness of the conductor. Of these, conductor loss is greatly affected by the frequency of the signal due to the skin effect. The skin effect is a phenomenon in which electrical signals pass through the conductor surface at higher frequencies. If the conductor surface is uneven, the path becomes longer and the transmission loss increases. Therefore, to reduce conductor loss, the circuit surface must be smooth.

Issues with hydrogen peroxide etchant

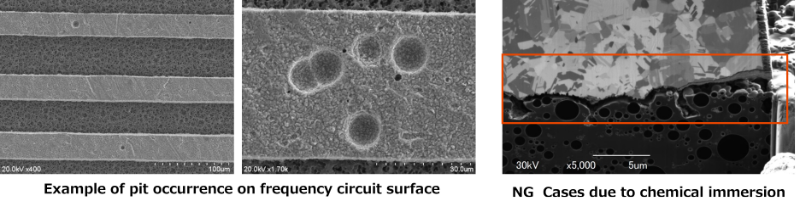

Sulfuric acid-hydrogen peroxide etchant, which is conventionally used as a seed layer etchant in the MSAP process, has the problem that pits are easily generated on the circuit. This results in a low smoothness of the circuit surface, and there is a concern that transmission loss may increase. In addition, the chemical can seep into the interface between the substrate and the circuit, causing undercuts.

Copper Seed Layer Etchant Melstrip SE-400

Therefore, we have developed an etchant that does not use hydrogen peroxide for etching and achieves a smooth etching surface. Meltstrip SE-400, a copper seed layer etchant using iron as an oxidant, has the following features.

- ・Copper Seed Layer Etchant for MSAP copper foil seed layer

- ・After etching, rectangular copper wiring is obtained.

- ・Rectangle is maintained even when over-etched

- ・Smooth copper surface after etching

- ・Iron-based etchant does not self-decompose, making it easy to handle and control the solution after a pause.

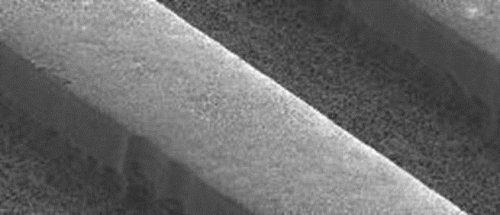

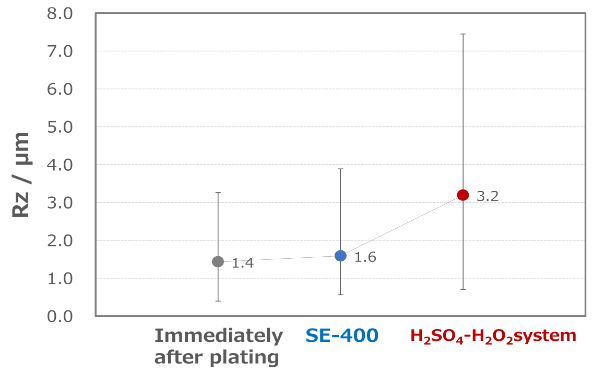

Smoothness after etching

The change in surface roughness due to etching was measured. Although surface roughness increased with etching in the sulfuric acid-hydrogen peroxide etchant, the use of SE-400 made it possible to maintain a smooth copper surface after etching.

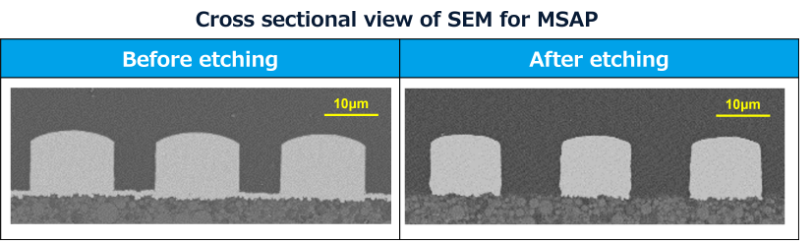

Application example of SE-400

The Meltstrip SE-400 not only maintains the smoothness of the circuit surface, but also achieves a rectangular, undercut-free circuit shape.

Contact

Please feel free to contact us with requests for more detailed characteristic data, or to discuss applications or prototypes.

We will reply to you by e-mail first.