Environmental Activities

Contribute to the improvement of the environment around the world by correctly knowing and improving the environmental risks and impacts arising from our products and business activities.

We will strictly control chemical substances and strive to promote environmentally friendly products.

Management of Environmentally Hazardous Substances

Meltex has offices with various experimental and manufacturing functions, and chemical substances are purchased, consumed, and stored at each location.

These operations are performed in accordance with our regulations, including compliance with legal requirements, and annual audits confirm their adequacy.

In addition, we monitor the management of chemical substances, energy, and other material balances.

Manufacturing Engineering

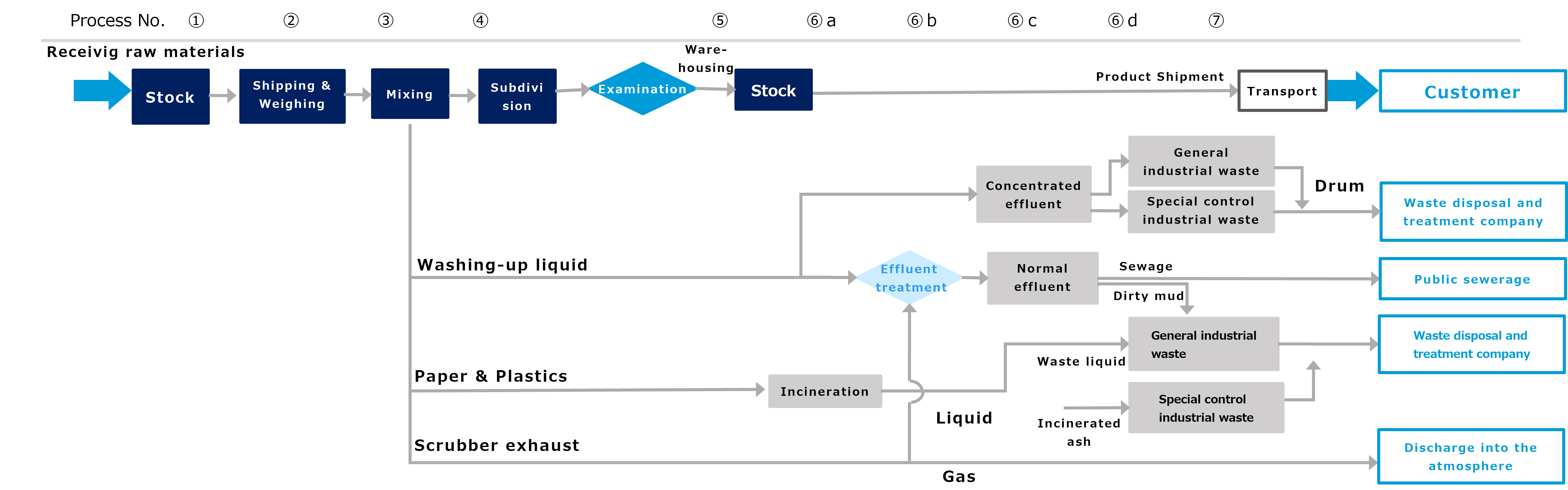

The manufacturing process at the production plant is as follows

Typical production flow diagram of a production plant.

Energy Consumed

All of our offices monitor energy consumption on a monthly basis.

In particular, the Kumagaya factory has introduced a system that not only sets targets for energy use, but also sets an upper limit for instantaneous energy use and activates an alarm to control it so that the upper limit is not exceeded.

Chemical Consumption and Management

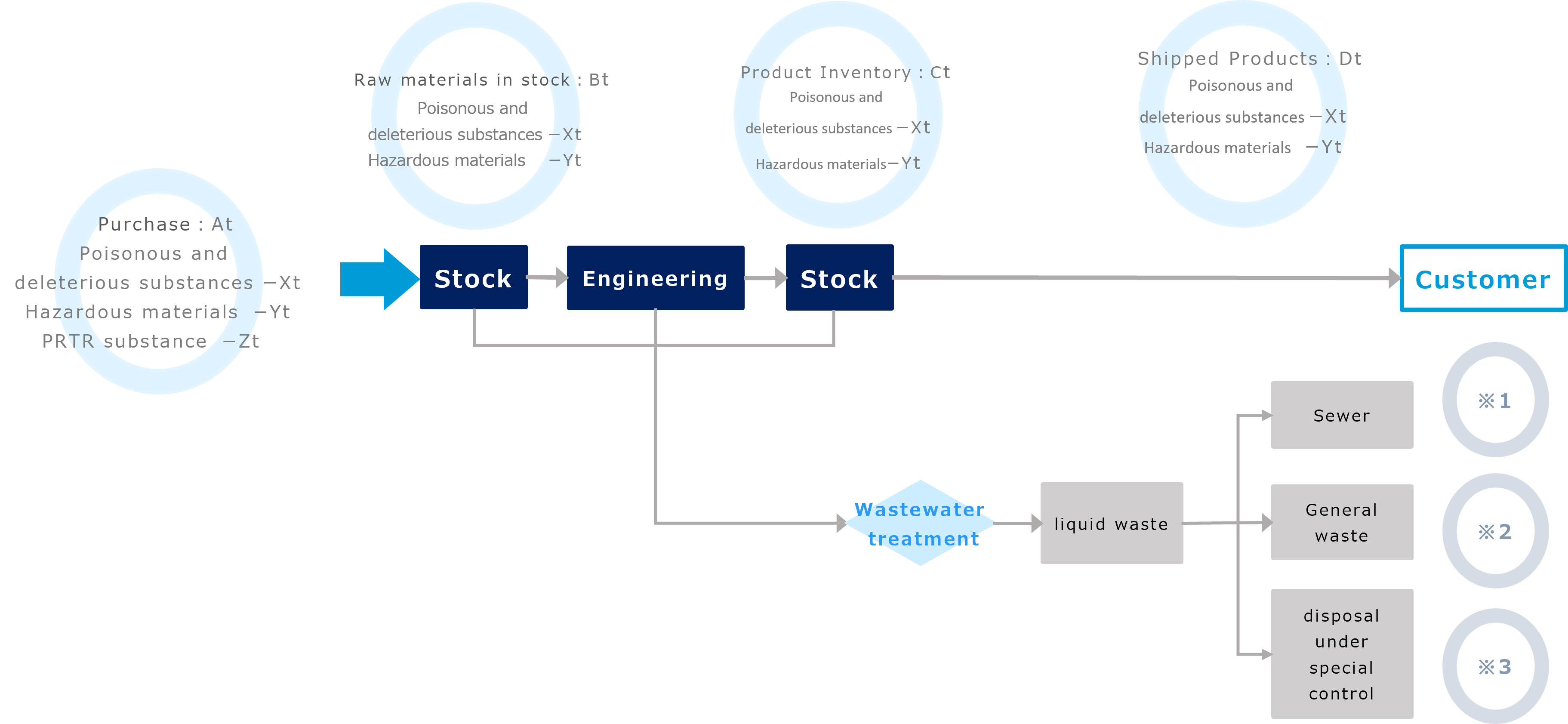

Substances that require special legal controls for raw materials and products are purchased, stored, and used. The overall flow and substance balance are shown here. Inventory, purchase, and shipment volumes are monitored annually.

Balance of environmental chemical substances at Kumagaya factory

Fiscal Year 2019 (April 2019 - March 2020)

※1:PRTR substances - approx. 946 kg

※strong acid and alkali - approx 27,022Kg

Management of Toxic and Hazardous Substances and Hazardous Materials

Our raw materials, inventory, and products contain certain toxic and hazardous substances, hazardous materials, and substances regulated under the PRTR law. We strictly monitor the quantities of these substances and manage them in accordance with the law.

Waste Disposal

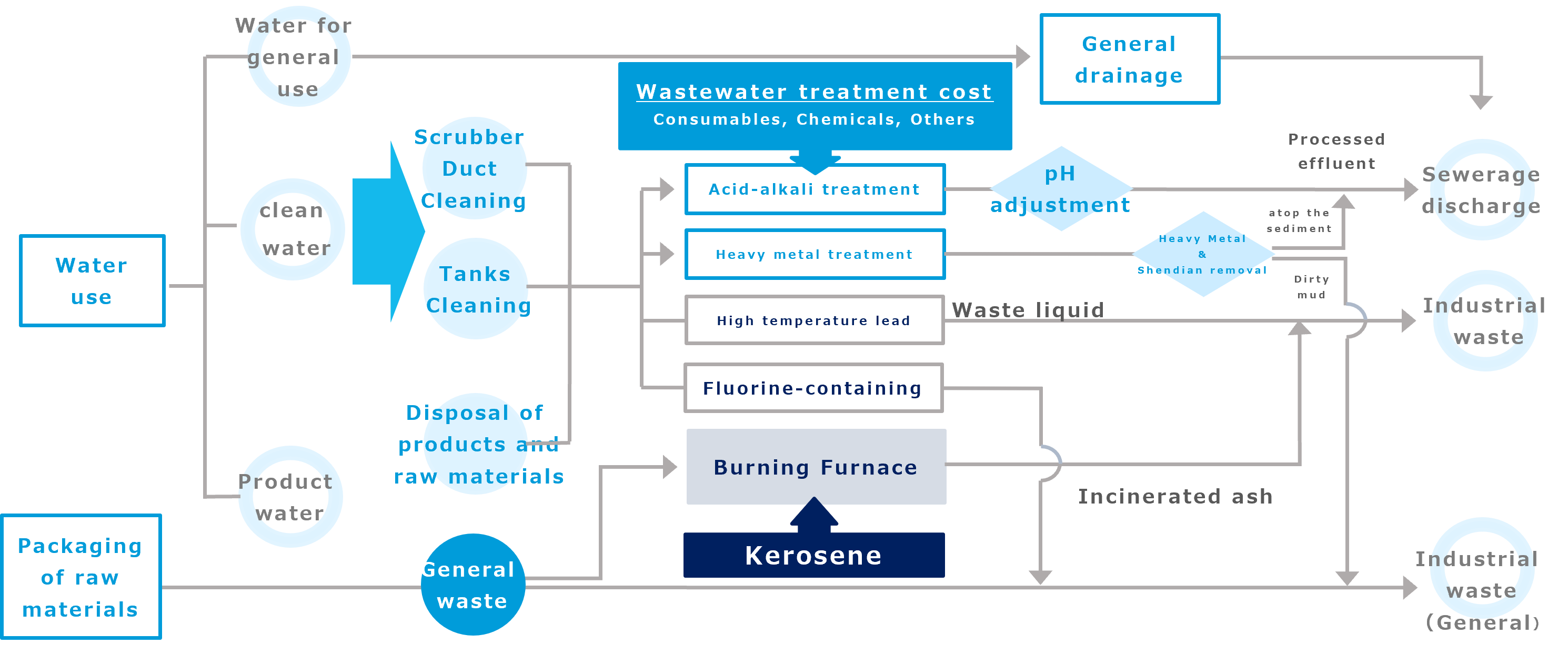

Environmentally hazardous substances emitted from each process are disposed of appropriately (within legal limits) as liquid waste and waste.

Material balance of industrial waste and liquid waste treatment processes

Fiscal Year 2019 (April 2019 - March 2020)

Amount of water used: about 9,600㎥

Sewerage volume: about 56,600㎥

Industrial waste (special pipe waste: approx. 25,137 kg, general waste: approx. 75,870 kg)

遵法

生産・研究活動に関係する法規は常時チェックされ、遵守すべき項目を明確化して全社で共有・管理しています。

これらの項目の遵法状況を毎年の内部監査で確認します。

Recycling of etchant

Meltex has been involved in the recycling of used etchant since the 1970s. We continue to provide technology to collect used etchant from our customers, recycle the refill solution and copper sulfate, respectively, and make effective use of them. This has become a recycling-oriented service model that does not generate a large amount of industrial waste from our customers and has a low environmental impact.

Environmental Protection Activities

Led by the members of "Environment Eleven," we are working on environmental load reduction activities under the life cycle-conscious environmental targets and also participating in activities such as cleanups and tree planting around our business sites.