Non-Cyanide type immersion gold plating

Melplate AU-7770

Chemicals

Semiconductor

Plating

Gold

Melplate AU-7770

◆Features

1. Uniform gold film thickness can be obtained

2. Less localized corrosion on nickel deposit

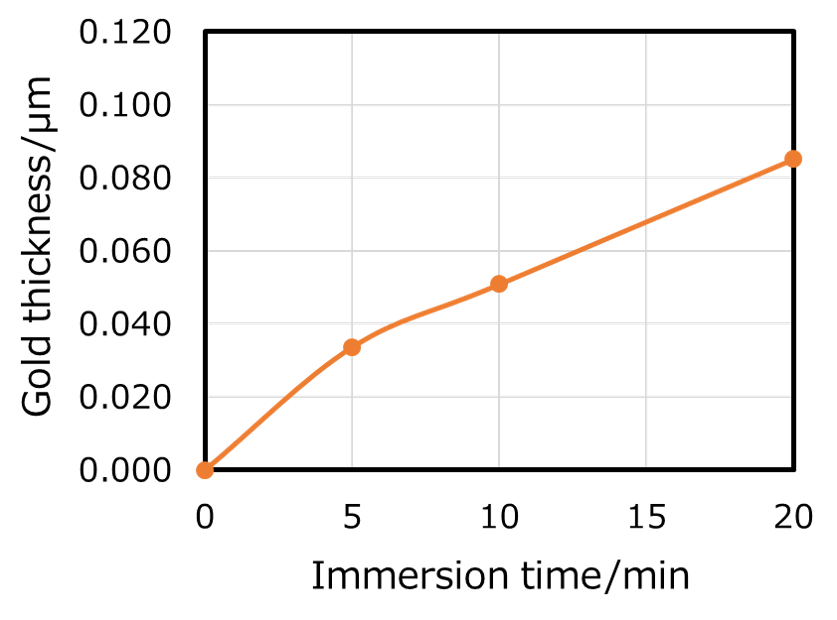

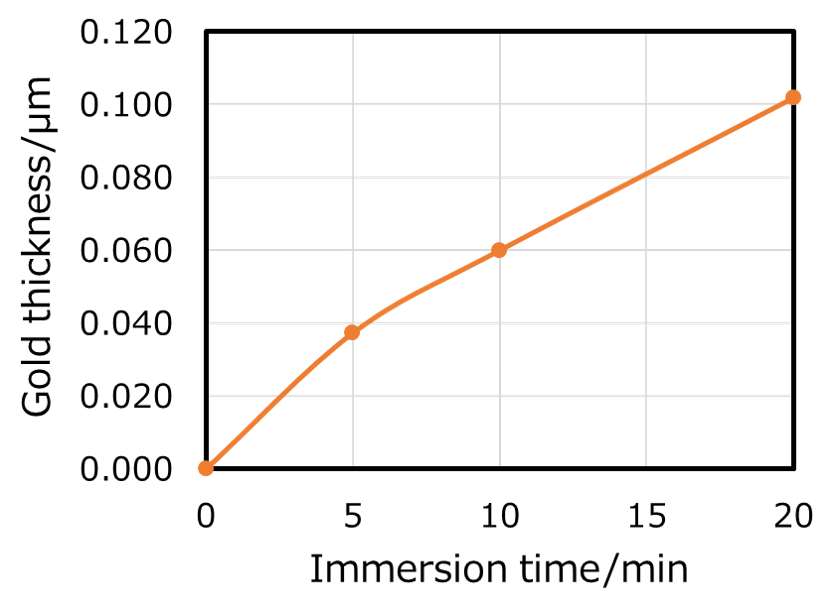

3. Plating rate: 0.04-0.06 μm/10 min

1. Uniform gold film thickness can be obtained

2. Less localized corrosion on nickel deposit

3. Plating rate: 0.04-0.06 μm/10 min

Cyan free

Inhibits erosion of underlying nickel film

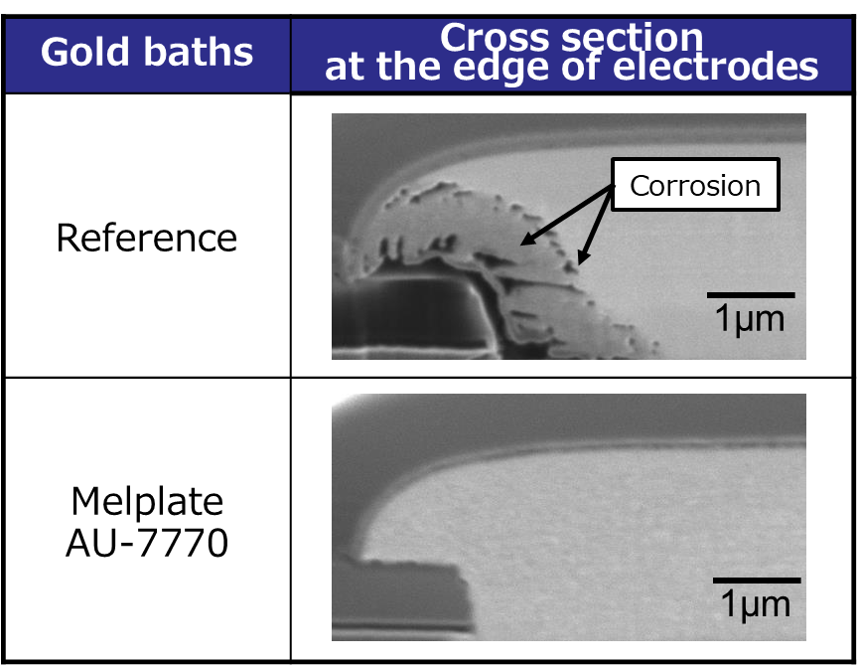

In the case of EN/EP/IG coating composition, the gold immersion deposition process causes preferential dissolution of nickel (galvanic corrosion) due to the difference in electrode potential between nickel and palladium at the electrode edge, which erodes the nickel coating layer (top photo: reference).

Melplate AU-7770 effectively suppresses galvanic corrosion and allows deposition of immersion gold plating without eroding the underlying nickel layer.

Melplate AU-7770 effectively suppresses galvanic corrosion and allows deposition of immersion gold plating without eroding the underlying nickel layer.