Copper seed etchant for semi-additive process (SAP)

Melstrip SE-300

Chemicals

PCB

Etching

Copper

Melstrip SE-300

Melstrip SE-300 is a copper seed etchant specially designed for semi-additive process. Melstrip SE-300 inhibits undercut and decrease of pattern width effectively and forms superior pattern shape.

◆Features

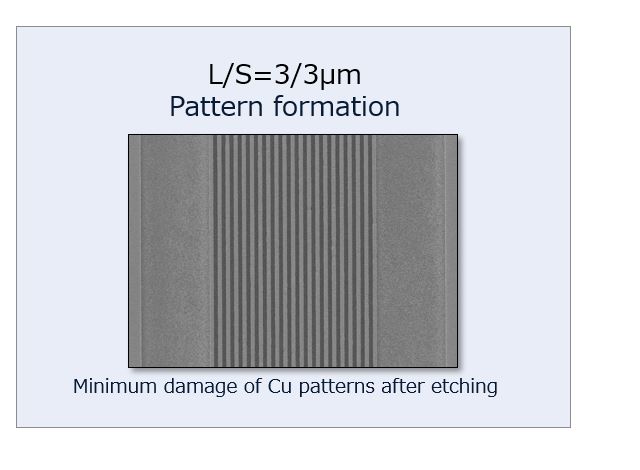

1. Melstrip SE-300 etches electroless copper deposit more preferentially than electrytic copper deposit: High selectivety to elecroless seed layer etching.

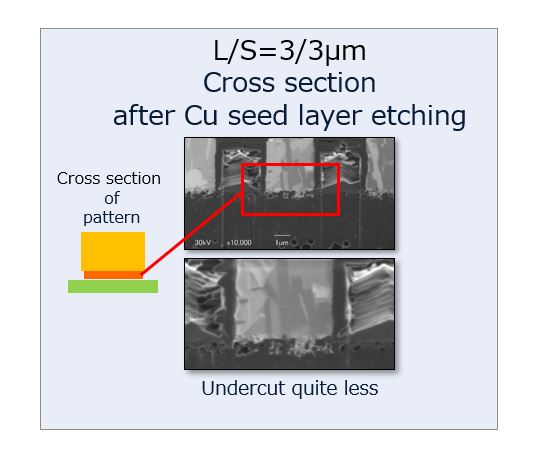

2. Preferance etching for elecroless copper doposit contirubutes suppression of undercut of elecrolytic copper patterns, leading to fine pattern formation.

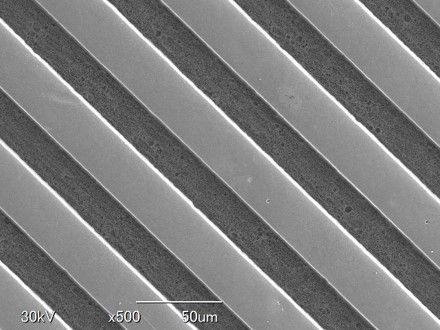

3. Flat and smooth copper surface is achieved after seed layer etching.

4. The oxidant used in Melstrip SE-300 is not self-dicomposed: The working solution is much stabler than conventional sulfuric acid-hydrogen peroxide type etchant.

5. Easy bath control based on analysis of bath components.

◆Features

1. Melstrip SE-300 etches electroless copper deposit more preferentially than electrytic copper deposit: High selectivety to elecroless seed layer etching.

2. Preferance etching for elecroless copper doposit contirubutes suppression of undercut of elecrolytic copper patterns, leading to fine pattern formation.

3. Flat and smooth copper surface is achieved after seed layer etching.

4. The oxidant used in Melstrip SE-300 is not self-dicomposed: The working solution is much stabler than conventional sulfuric acid-hydrogen peroxide type etchant.

5. Easy bath control based on analysis of bath components.

Fine pattern after seed layer etching

Cross section of copper pattern after seed layer etching

Surface of copper pattern after seed layer etching

Reduction of transmission loss is the key technology for the next-generation communication standard like 5G. For this, flat copper conductive surface on flat dielectric substrates is high required. Melstrip SE-300 is preferable to achieve flat copper surface after etching compared with a conventional sulfuric acid-hydrogen peroxide type copper etchant.