半导体铝电极的无电镀UBM形成工艺

Melplate UBM Process

Chemicals

Semiconductor

Plating

EN/EP/IG

Melplate UBM Process

1. 在铝或各种铝合金电极上实现均匀平整的沉积,具有优异的屏蔽性能,且对电极损伤最小。

◆特点

1. 在铝或各种铝合金电极上实现均匀平整的沉积,具有优异的屏蔽性能,且对电极损伤最小。

2. 即使在微小电极上也能实现选择性化学沉积

3. 完全无氰化物

4. 良好的附着力和焊接性能

◆特点

1. 在铝或各种铝合金电极上实现均匀平整的沉积,具有优异的屏蔽性能,且对电极损伤最小。

2. 即使在微小电极上也能实现选择性化学沉积

3. 完全无氰化物

4. 良好的附着力和焊接性能

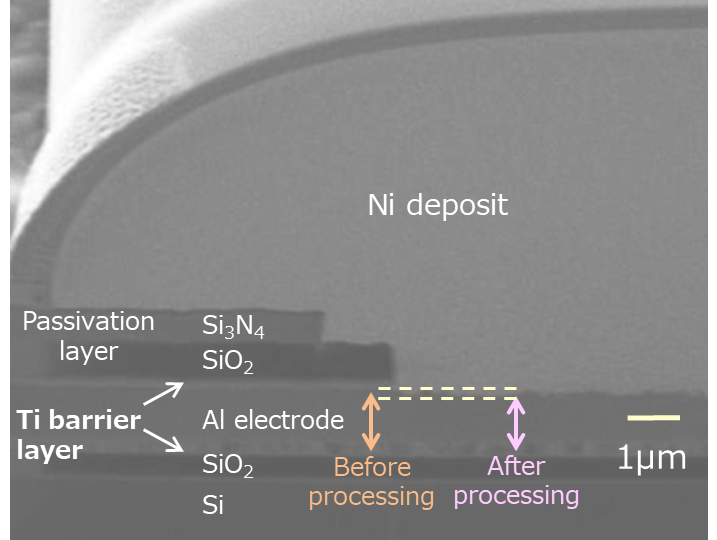

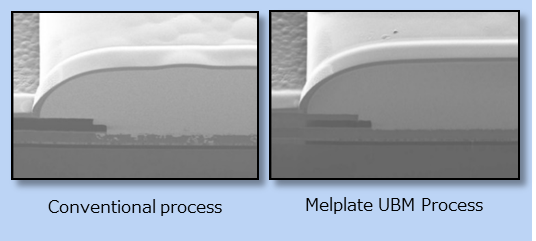

Effective suppression of nickel spike into aluminum electrodes

In conventional process, localized corrosion of aluminum electrodes causes the deep penetration of nickel plating into aluminum electrodes, so-called "nickel spikes" (left). Melplate UBM process suppress this spikes due to optimized zincate treatments. The first zincate treatment is specialized in suppressing localized corrosion of aluminum electrode and the second one contributes to improve the adhesion of electroless nickel plating.

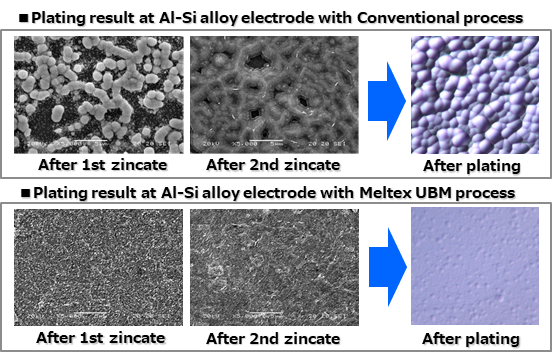

Smooth and uniform electroless deposition

In the conventional process, the surface morphology after zincate treatment may be rough, depending on the material. Melplate UBM process enables smooth deposition of electroless plating on various aluminum alloy electrode materials by forming uniform and dense zinc replacement deposit through optimization of the pretreatment process.