SAP工艺用铜种子层蚀刻剂

Melstrip SE-300

Chemicals

PCB

Etching

Copper

Melstrip SE-300

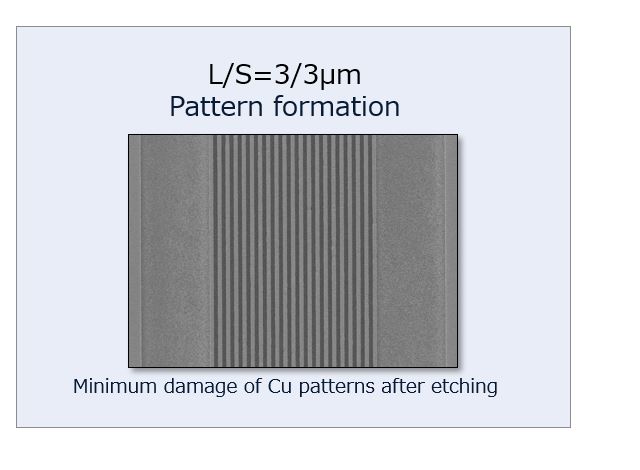

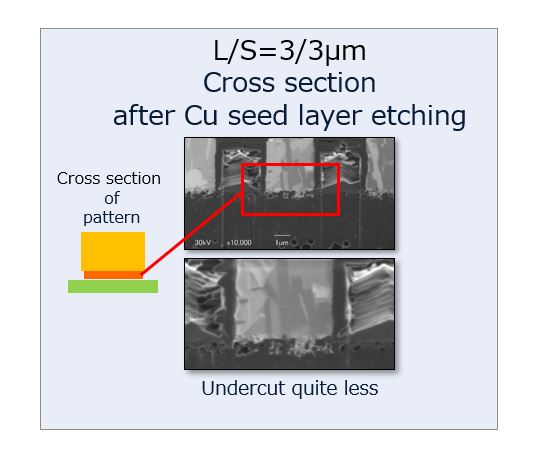

Melstrip SE-300 是专为半加成法(SAP)设计的铜种子层蚀刻液。可有效抑制图形下蚀和线宽缩小,形成优异图形。

◆特点

1.对化学镀铜层的蚀刻选择性高于电镀铜层。

2.优先蚀刻化学镀铜,有助于抑制电镀铜图形的下蚀,形成精细图形。

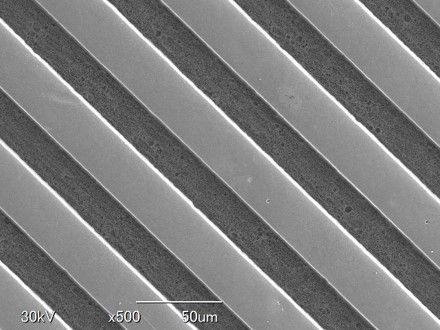

3.蚀刻后铜表面平整光滑。

4.使用的氧化剂不自分解,工作液比传统硫酸-过氧化氢型蚀刻液更稳定。

5.可通过成分分析进行简便的槽液管理。

◆特点

1.对化学镀铜层的蚀刻选择性高于电镀铜层。

2.优先蚀刻化学镀铜,有助于抑制电镀铜图形的下蚀,形成精细图形。

3.蚀刻后铜表面平整光滑。

4.使用的氧化剂不自分解,工作液比传统硫酸-过氧化氢型蚀刻液更稳定。

5.可通过成分分析进行简便的槽液管理。

Fine pattern after seed layer etching

Cross section of copper pattern after seed layer etching

Surface of copper pattern after seed layer etching

Reduction of transmission loss is the key technology for the next-generation communication standard like 5G. For this, flat copper conductive surface on flat dielectric substrates is high required. Melstrip SE-300 is preferable to achieve flat copper surface after etching compared with a conventional sulfuric acid-hydrogen peroxide type copper etchant.